Polyester Enameled Copper Clad Aluminium Wire Class130

| Mofuta oa Sehlahisoa | PEW/130 |

| Tlhaloso e Akaretsang | 130 Kereiti Polyester |

| Tataiso ea IEC | IEC60317-3 |

| Index ea Mocheso (°C) | 130 |

| Solderability | Ha e chesehe |

| Tataiso ea NEMA | NEMA MW 5-C |

| UL-Amohelo | / |

| Li-diameter tse fumanehang | 0.08mm-1.15mm |

| Thempereichara e Nolofatsang (°C) | 240 |

| Thermal Shock Temperature(°C) | 155 |

| Bophara ba lebitso(mm) | Mamello ea conductor(mm) | G1 | G2 | Motlakase o fokolang oa motlakase (V) | Bonyane bo bolelele (%) | ||

| Botenya bo fokolang ba filimi | Feletseng boholo ba bophara ba bokantle(mm) | Botenya bo fokolang ba filimi | Feletseng boholo ba bophara ba bokantle(mm) | G1 | |||

| 0.1 | 0.003 | 0.005 | 0.115 | 0.009 | 0.124 | 1200 | 11 |

| 0.12 | 0.003 | 0.006 | 0.137 | 0.01 | 0.146 | 1600 | 11 |

| 0.15 | 0.003 | 0.0065 | 0.17 | 0.0115 | 0.181 | 1800 | 15 |

| 0.17 | 0.003 | 0.007 | 0.193 | 0.0125 | 0.204 | 1800 | 15 |

| 0.19 | 0.003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900 | 15 |

| 0.2 | 0.003 | 0.008 | 0.225 | 0.0135 | 0.238 | 2000 | 15 |

| 0.21 | 0.003 | 0.008 | 0.237 | 0.014 | 0.25 | 2000 | 15 |

| 0.23 | 0.003 | 0.009 | 0.257 | 0.016 | 0.271 | 2100 | 15 |

| 0.25 | 0.004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 15 |

| 0.27 | 0.004 | 0.009 | 0.3 | 0.0165 | 0.318 | 2300 | 15 |

| 0.28 | 0.004 | 0.009 | 0.31 | 0.0165 | 0.328 | 2400 | 15 |

| 0.3 | 0.004 | 0.01 | 0.332 | 0.0175 | 0.35 | 2400 | 16 |

| 0.32 | 0.004 | 0.01 | 0.355 | 0.0185 | 0.371 | 2400 | 16 |

| 0.33 | 0.004 | 0.01 | 0.365 | 0.019 | 0.381 | 2500 | 16 |

| 0.35 | 0.004 | 0.01 | 0.385 | 0.019 | 0.401 | 2600 | 16 |

| 0.37 | 0.004 | 0.011 | 0.407 | 0.02 | 0.425 | 2600 | 17 |

| 0.38 | 0.004 | 0.011 | 0.417 | 0.02 | 0.435 | 2700 | 17 |

| 0.4 | 0.005 | 0.0115 | 0.437 | 0.02 | 0.455 | 2800 | 17 |

| 0.45 | 0.005 | 0.0115 | 0.488 | 0.021 | 0.507 | 2800 | 17 |

| 0.5 | 0.005 | 0.0125 | 0.54 | 0.0225 | 0.559 | 3000 | 19 |

| 0.55 | 0.005 | 0.0125 | 0.59 | 0.0235 | 0.617 | 3000 | 19 |

| 0.57 | 0.005 | 0.013 | 0.61 | 0.024 | 0.637 | 3000 | 19 |

| 0.6 | 0.006 | 0.0135 | 0.642 | 0.025 | 0.669 | 3100 | 20 |

| 0.65 | 0.006 | 0.014 | 0.692 | 0.0265 | 0.723 | 3100 | 20 |

| 0.7 | 0.007 | 0.015 | 0.745 | 0.0265 | 0.775 | 3100 | 20 |

| 0.75 | 0.007 | 0.015 | 0.796 | 0.028 | 0.829 | 3100 | 20 |

| 0.8 | 0.008 | 0.015 | 0.849 | 0.03 | 0.881 | 3200 | 20 |

| 0.85 | 0.008 | 0.016 | 0.902 | 0.03 | 0.933 | 3200 | 20 |

| 0.9 | 0.009 | 0.016 | 0.954 | 0.03 | 0.985 | 3300 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0.0315 | 1.037 | 3400 | 20 |

| 1 | 0.01 | 0.0175 | 1.06 | 0.0315 | 1.094 | 3500 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0.0325 | 1.196 | 3500 | 20 |

1. DC resistivity

DC resistivity ea terata ea CCA ke hoo e ka bang makhetlo a 1.45 a terata ea koporo;ka khanyetso e tšoanang, terata ea CCA e ka ba 1/2 e boima ea terata ea koporo.

2. Solderability e ntle

CCA terata e apesitsoe lera la koporo concentric, kahoo e na le solderability e tšoanang le ea koporo terata 'me ha e hloke phekolo e khethehileng joaloka terata ea aluminium;

3. Boima bo bobebe

Boima ba terata ea CCA ke 1/3 ea terata ea koporo ea bophara bo lekanang;e sebetsang haholo ho fokotsa boima ba likhoele le likhoele.

| Mofuta oa Sehlahisoa | Tlhaloso e Akaretsang | Litšobotsi |

| PEW/130 | Polyester ea boleng ba 130 | Ho hanyetsa mocheso o motle le matla a mochine. |

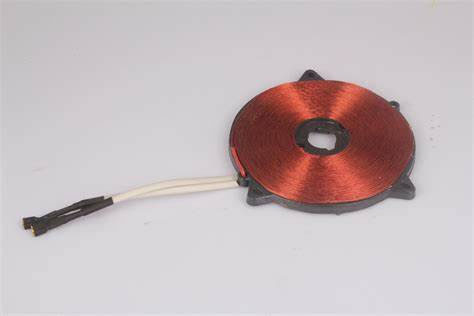

1.Koele ea lentsoe ea sebuela-hōle.Khafetsa ea eona e ka fihla ho 500Hz-1600Hz, E ka fokotsa boima ba ho sisinyeha le ho boloka ts'epo e phahameng.

2.Monitor kheloha khoele.E ka fokotsa mocheso oa coil, ea ntlafatsa botsitso ba setšoantšo, ea eketsa bophelo ba tšebeliso.

3.Hlokomela coil ea degaussing.E ka fokotsa litšenyehelo tsa sehlahisoa.

4.Enjene e tloaelehileng, transformer e bohareng.

Khetho ea Bobbin

| Mofuta oa Spool | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Boima ba Spool [g] | nom.boima ba terata [kg] | e kgothaletswa bakeng sa boholo ba terata [mm] | spools ka lebokose | |||||

| Enameled Copper Wire | Enameled Aluminium Wire | Enameled CCA Wire | ||||||||||||

| 10% CCA | 30% CCA | 40% CCA | 50% CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04~0.19 | 4 |

| PT-10 | 160 | 22 | 230 | 200 | 180 | 0.45 | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20~0.29 | 2/4 |

| PT-15 | 180 | 22 | 230 | 200 | 200 | 0.54 | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30~0,62 | 1/2 |

| PT-25 | 215 | 32 | 280 | 250 | 230 | 0.75 | 28 | 10 | 11 | 13 | 14 | 15 | 0.65~4.00 | 1 |

| PT-60 | 270 | 32 | 406 | 350 | 300 | 2.05 | 80 | 24 | 24 | 28 | 32 | 35 | 0.65~4.00 | 1 |

Ho paka