Polyurethane Enameled Copper Clad Aluminium Wire Class180

| Mofuta oa Sehlahisoa | UEW/180 |

| Tlhaloso e Akaretsang | 180Grade Straight Welded Polyurethane |

| Tataiso ea IEC | IEC 60317-51,IEC 60317-20 |

| Index ea Mocheso (°C) | 180 |

| Solderability | 390 ℃/3s E ka rekisoa |

| Tataiso ea NEMA | MW 82, MW79, MW75 |

| UL-Amohelo | EE |

| Li-diameter tse fumanehang | 0.08mm-1.15mm |

| Thempereichara e Nolofatsang (°C) | 230 |

| Thermal Shock Temperature(°C) | 200 |

| Bophara ba lebitso(mm) | Mamello ea conductor(mm) | G1 | G2 | Motlakase o fokolang oa motlakase (V) | Bonyane bo bolelele (%) | ||

| Botenya bo fokolang ba filimi | Feletseng boholo ba bophara ba bokantle(mm) | Botenya bo fokolang ba filimi | Feletseng boholo ba bophara ba bokantle(mm) | G1 | |||

| 0.1 | 0.003 | 0.005 | 0.115 | 0.009 | 0.124 | 1200 | 11 |

| 0.12 | 0.003 | 0.006 | 0.137 | 0.01 | 0.146 | 1600 | 11 |

| 0.15 | 0.003 | 0.0065 | 0.17 | 0.0115 | 0.181 | 1800 | 15 |

| 0.17 | 0.003 | 0.007 | 0.193 | 0.0125 | 0.204 | 1800 | 15 |

| 0.19 | 0.003 | 0.008 | 0.215 | 0.0135 | 0.227 | 1900 | 15 |

| 0.2 | 0.003 | 0.008 | 0.225 | 0.0135 | 0.238 | 2000 | 15 |

| 0.21 | 0.003 | 0.008 | 0.237 | 0.014 | 0.25 | 2000 | 15 |

| 0.23 | 0.003 | 0.009 | 0.257 | 0.016 | 0.271 | 2100 | 15 |

| 0.25 | 0.004 | 0.009 | 0.28 | 0.016 | 0.296 | 2300 | 15 |

| 0.27 | 0.004 | 0.009 | 0.3 | 0.0165 | 0.318 | 2300 | 15 |

| 0.28 | 0.004 | 0.009 | 0.31 | 0.0165 | 0.328 | 2400 | 15 |

| 0.3 | 0.004 | 0.01 | 0.332 | 0.0175 | 0.35 | 2400 | 16 |

| 0.32 | 0.004 | 0.01 | 0.355 | 0.0185 | 0.371 | 2400 | 16 |

| 0.33 | 0.004 | 0.01 | 0.365 | 0.019 | 0.381 | 2500 | 16 |

| 0.35 | 0.004 | 0.01 | 0.385 | 0.019 | 0.401 | 2600 | 16 |

| 0.37 | 0.004 | 0.011 | 0.407 | 0.02 | 0.425 | 2600 | 17 |

| 0.38 | 0.004 | 0.011 | 0.417 | 0.02 | 0.435 | 2700 | 17 |

| 0.4 | 0.005 | 0.0115 | 0.437 | 0.02 | 0.455 | 2800 | 17 |

| 0.45 | 0.005 | 0.0115 | 0.488 | 0.021 | 0.507 | 2800 | 17 |

| 0.5 | 0.005 | 0.0125 | 0.54 | 0.0225 | 0.559 | 3000 | 19 |

| 0.55 | 0.005 | 0.0125 | 0.59 | 0.0235 | 0.617 | 3000 | 19 |

| 0.57 | 0.005 | 0.013 | 0.61 | 0.024 | 0.637 | 3000 | 19 |

| 0.6 | 0.006 | 0.0135 | 0.642 | 0.025 | 0.669 | 3100 | 20 |

| 0.65 | 0.006 | 0.014 | 0.692 | 0.0265 | 0.723 | 3100 | 20 |

| 0.7 | 0.007 | 0.015 | 0.745 | 0.0265 | 0.775 | 3100 | 20 |

| 0.75 | 0.007 | 0.015 | 0.796 | 0.028 | 0.829 | 3100 | 20 |

| 0.8 | 0.008 | 0.015 | 0.849 | 0.03 | 0.881 | 3200 | 20 |

| 0.85 | 0.008 | 0.016 | 0.902 | 0.03 | 0.933 | 3200 | 20 |

| 0.9 | 0.009 | 0.016 | 0.954 | 0.03 | 0.985 | 3300 | 20 |

| 0.95 | 0.009 | 0.017 | 1.006 | 0.0315 | 1.037 | 3400 | 20 |

| 1 | 0.01 | 0.0175 | 1.06 | 0.0315 | 1.094 | 3500 | 20 |

| 1.05 | 0.01 | 0.0175 | 1.111 | 0.032 | 1.145 | 3500 | 20 |

| 1.1 | 0.01 | 0.0175 | 1.162 | 0.0325 | 1.196 | 3500 | 20 |

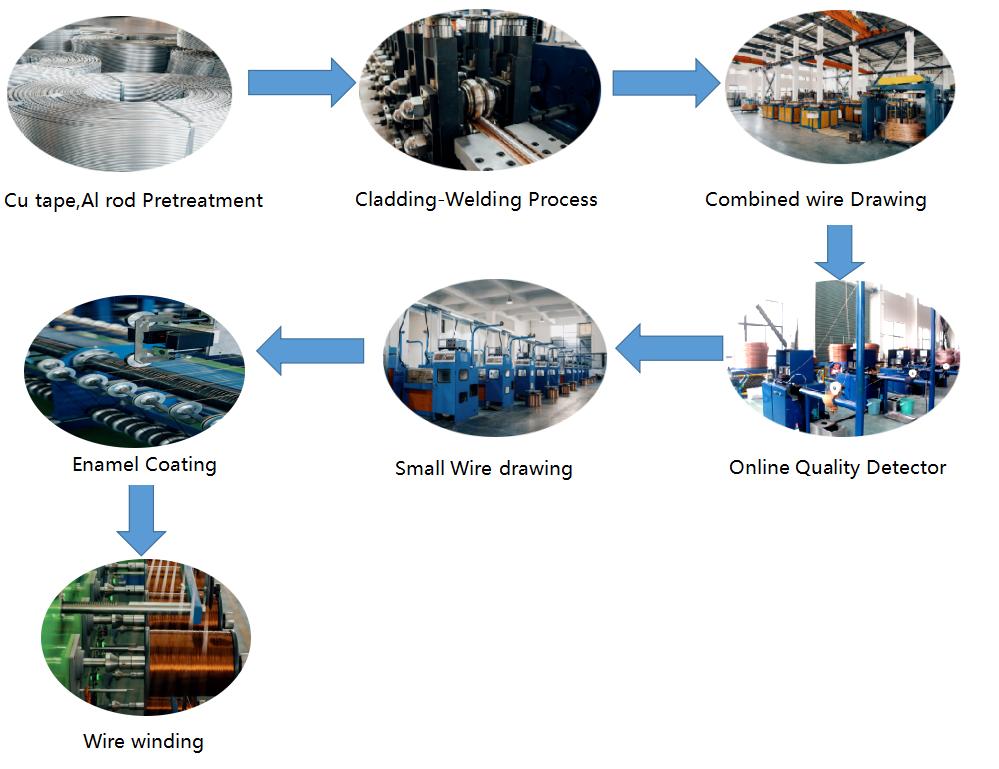

1. Ts'ebetso e ntle ea motlakase, e tšoanang le mohala oa koporo ka maqhubu a phahameng ka holimo ho 5MHZ.

2. Boloka lisebelisoa tsa koporo le ho fokotsa litšenyehelo.Boima ba terata ea aluminium e entsoeng ka koporo e nyane ho feta ea terata e hloekileng ea koporo, 'me bolelele ba eona ke makhetlo a 2,5 ho feta terata e hloekileng ea koporo ea boima bo lekanang.

3. Mocheso o bonolo oa ho senya o phahame ho feta UEW/155;mocheso o otlolohileng oa soldering ke 390 ° C;ho bonolo ho daea;tahlehelo e tlase ea dielectric ka maqhubu a phahameng;ha ho na sekoti sa metsi a letsoai

| Mofuta oa Sehlahisoa | Tlhaloso e Akaretsang | Litšobotsi |

| UEW/180 | 180Grade Straight Welded Polyurethane | Mocheso o bonolo oa ho senya o phahame ho feta UEW/155;mocheso o otlolohileng oa soldering ke 390 ° C;ho bonolo ho daea;tahlehelo e tlase ea dielectric ka maqhubu a phahameng;ha ho na sekoti sa metsi a letsoai |

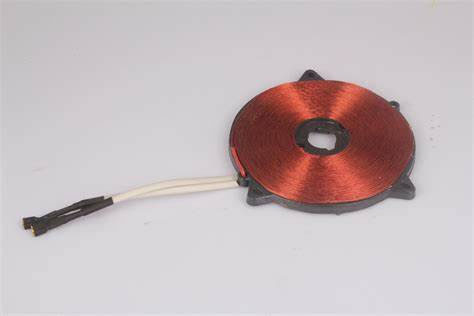

1.Relays, li-micro-motors, li-transformer tse nyenyane, li-coil tse khantšang, li-valve tsa ho emisa metsi, lihlooho tsa magnetic, li-coil bakeng sa lisebelisoa tsa puisano.

2. Transformer winding ka induction cooker.E ka fokotsa boima ba lihlahisoa.

3.Induction cooker chassis.E ka fokotsa litšenyehelo tsa tlhahiso.

4.Sodium lebone ballast.E ka fokotsa boima ba sehlahisoa.

5.Various windings ea aerospace liletsa.E ka fokotsa boima ba sehlahisoa.

6.Li-Coils ho Induction Cooker Chassis, Li-coil tsa Ring Transformer ka Lisebelisoa tsa Audio tsa High Fidelity.

Khetho ea Bobbin

| Mofuta oa Spool | d1 [mm] | d4 [mm] | I1 [mm] | I2 [mm] | d14 [mm] | Boima ba Spool [g] | nom.boima ba terata [kg] | e kgothaletswa bakeng sa boholo ba terata [mm] | spools ka lebokose | |||||

| Enameled Copper Wire | Enameled Aluminium Wire | Enameled CCA Wire | ||||||||||||

| 10% CCA | 30% CCA | 40% CCA | 50% CCA | |||||||||||

| PT-4 | 124 | 22 | 200 | 170 | 140 | 0.23 | 6 | 2 | 2.5 | 3 | 3.2 | 3.5 | 0.04~0.19 | 4 |

| PT-10 | 160 | 22 | 230 | 200 | 180 | 0.45 | 15 | 4.5 | 5 | 6 | 6.5 | 7.5 | 0.20~0.29 | 2/4 |

| PT-15 | 180 | 22 | 230 | 200 | 200 | 0.54 | 20 | 6.5 | 7 | 8 | 8.5 | 9 | 0.30~0,62 | 1/2 |

| PT-25 | 215 | 32 | 280 | 250 | 230 | 0.75 | 28 | 10 | 11 | 13 | 14 | 15 | 0.65~4.00 | 1 |

| PT-60 | 270 | 32 | 406 | 350 | 300 | 2.05 | 80 | 24 | 24 | 28 | 32 | 35 | 0.65~4.00 | 1 |

Ho paka